Service hotline0086 0573-87098000

Add

No.11, Jinchang Road, Haining Economic Development Zone

CN

CN

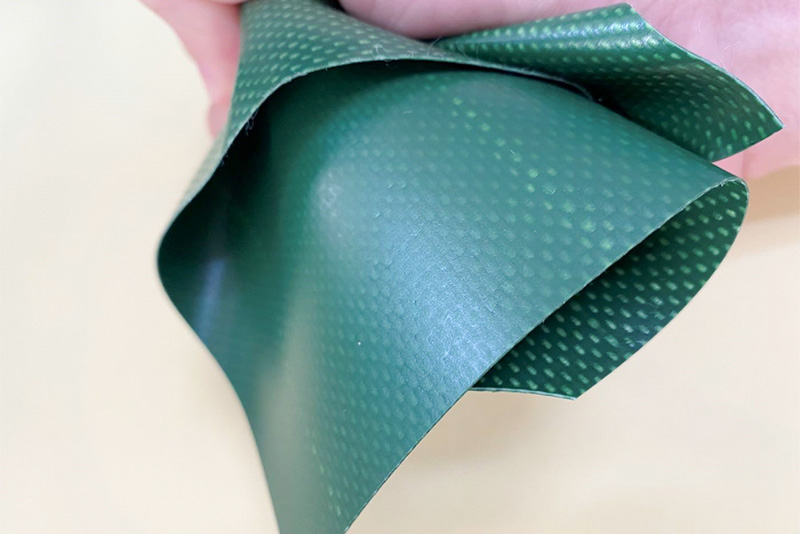

In daily operation, the thermal insulation film is used […]

In daily operation, the thermal insulation film is used to adhere the rubbing paper. First, use a scraper to drive out the nutrients from the core of the rubbing paper to the surrounding area. Then slowly pull up the rubbing film from one end and stick it on the glass, and at the same time use a clean soft cloth or scraper to scrape the rubbing paper in the direction of adhesion until all the rubbing paper is adhered.

First, spray a little more water with one or two drops of detergent (alkaline) on the glass, and let it drip down.It is recommended that buyers in the north - decide whether to use the following paste methods according to their own working conditions.This method may not be suitable for external glazing in northern winter.Let me introduce to you an additional, easier way to adhere the rubbing paper.It is necessary to stick a little bit of self-adhesive paper,and use a clean soft cloth or a scraper to scrape the pasted piece in the direction of adhesion, and then follow the steps to stick the rubbing paper.

And when you pull the adhesive paper, you can't tear off the whole adhesive paper at once, so it can't help sticking easily, it will be very wrinkled and there will be many air bubbles inside.You can't be anxious to stick the rubbing paper, you must stick it slowly. And it is two people, who tear off the adhesive paper alone, and use a clean soft cloth or scraper to scrape the surface out of the air.

Before sticking the rubbing paper, the oil stains, stains and dust on the glass must be wiped clean. Then slowly lift the rubbing paper from one end of the insulation film and stick it to the glass.It is very troublesome to cause repeated postings.After pasting, cut off the film of the parallel branches with the blade insulation film, which will prevent it from being easily pasted after cutting the appropriate size first.First, cut the specifications of the rubbing film into specifications that are about 1cm to 2cm larger than the surface to be veneered.